Roofing systems form the backbone of any steel structure, yet purlin selection is often underestimated during design. Engineers usually face one common dilemma: choosing between Zed Purlin and C-Purlin. While both serve the same basic function, their structural behavior, load efficiency, and long-term performance differ significantly. Selecting the wrong profile can increase steel consumption, raise maintenance costs, and compromise safety.

This guide explains the technical differences between Zed Purlin and C-Purlin using engineering logic, Indian standards, and real performance data. The goal is to help engineers, fabricators, and project planners make informed decisions instead of relying on habit or guesswork.

Role of Purlins in Steel Roof Structures

Purlins act as secondary structural members that support roof sheeting and transfer loads to primary frames. These loads include dead load, live load, wind uplift, and sometimes seismic forces. According to IS 800:2007, improper design of secondary members can affect overall structural stability, especially in long-span buildings.

In modern pre-engineered buildings, purlins contribute heavily to weight optimization. Even small improvements in purlin efficiency can reduce total steel tonnage by 8–15 percent. Therefore, choosing the correct profile becomes a structural and economic decision, not just a fabrication choice.

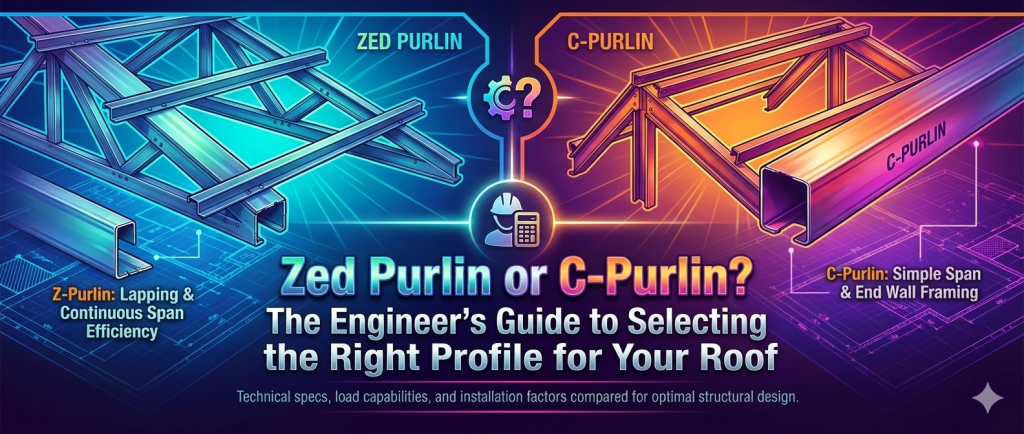

What Is a Zed Purlin?

A Zed Purlin has a Z-shaped cross-section designed specifically for continuity over multiple spans. The unique geometry allows overlapping at supports, creating a continuous beam effect. This overlap significantly improves bending strength and load distribution without increasing section thickness.

Zed Purlin systems are widely used in industrial sheds, warehouses, logistics parks, and large manufacturing units. Their ability to span longer distances makes them ideal for roofs exceeding 6–8 meters. As per IS 801:1975, cold-formed Z sections demonstrate higher structural efficiency under flexural loading compared to simple channel sections.

Government infrastructure projects and CPWD specifications increasingly recommend Zed Purlin for large roof systems due to material optimization and structural reliability.

What Is a C-Purlin?

C-Purlin features a channel-shaped cross-section and functions primarily as a simply supported member. Unlike Zed Purlin, it does not provide natural continuity at supports. As a result, bending moments remain higher, especially in longer spans.

C-Purlins are easier to fabricate and install, which makes them popular for small sheds, temporary structures, and low-rise buildings. However, when span lengths increase, C-Purlins require thicker gauges to control deflection. This leads to higher steel consumption and increased costs.

According to NBC 2016, simple-span secondary members are best suited for short spans and low wind zones, reinforcing the limited but valid use of C-Purlin systems.

Structural Comparison: Zed Purlin vs C-Purlin

From a structural engineering perspective, Zed Purlin consistently outperforms C-Purlin in large roof systems.

Zed Purlin offers superior load-carrying capacity due to its overlapping continuity. This reduces maximum bending moments and deflection. In contrast, C-Purlin behaves as an isolated member, carrying full load within a single span.

Span efficiency is another critical factor. Zed Purlin can comfortably span up to 8 meters depending on section size and load conditions. C-Purlin performs best under spans below 5 meters. Beyond that, serviceability limits become difficult to control.

Material efficiency also favors Zed Purlin. Data published by Steel Authority of India (SAIL) indicates that Zed sections can reduce steel usage by 10–15 percent compared to C sections for the same loading conditions.

Wind Load Performance in Indian Conditions

India experiences diverse wind zones, ranging from low-risk inland areas to high-risk coastal regions. According to IS 875 Part 3, basic wind speeds in coastal zones can reach 50 m/s. Roof uplift becomes a governing design factor in such regions.

Zed Purlin performs better under wind uplift due to its overlapping joints and improved restraint. This continuity reduces the risk of progressive failure during cyclonic conditions. C-Purlin systems often require additional sag rods or bracing, which increases both cost and installation complexity.

Corrosion Resistance and Service Life

Roof purlins are continuously exposed to moisture, temperature variation, and industrial pollutants. Galvanisation quality plays a major role in durability. Most Zed Purlin systems use galvanised steel with coating thickness between 120 and 275 GSM.

As per IS 277, higher zinc coating significantly extends service life in aggressive environments. Zed Purlin geometry also promotes better water drainage, reducing moisture retention at joints. C-Purlin systems may trap moisture, especially at lap joints, increasing corrosion risk over time.

For long-term projects, Zed Purlin offers superior durability with lower maintenance requirements.

When Does C-Purlin Make Sense?

C-Purlin still has its place in construction. Small sheds, temporary structures, and low-load applications benefit from its simplicity. Projects with tight budgets and short spans may find C-Purlin adequate.

However, engineers must always verify deflection limits and wind load effects. Blindly using C-Purlin for large spans can lead to serviceability issues and future retrofitting costs.

Why Zed Purlin Is the Preferred Choice Today

Modern industrial buildings demand efficiency, scalability, and sustainability. Zed Purlin aligns well with these goals. Its ability to handle longer spans, reduce steel usage, and perform better under wind loads makes it the preferred choice for pre-engineered buildings.

Many PEB manufacturers standardise Zed Purlin systems to comply with Make in India infrastructure and sustainability objectives. Reduced steel usage also lowers the carbon footprint, supporting environmentally responsible construction.

Why Engineers Trust Choice Prefab LLP for High-Performance PEB Solutions

Selecting the right purlin profile is only effective when backed by expert manufacturing and execution. This is where Choice Prefab LLP stands apart as one of the best PEB manufacturers in India. With a strong focus on engineering precision, Choice Prefab LLP delivers pre-engineered building solutions that meet the highest standards of safety, durability, and cost efficiency.

Choice Prefab LLP specialises in designing and manufacturing advanced steel structures using optimised Zed Purlin systems, ensuring superior load distribution and long-span performance. Every structure is engineered in compliance with IS 800, IS 801, IS 875, and NBC 2016, making them suitable for India’s diverse wind and seismic zones. This standards-driven approach results in lighter structures without compromising strength.

Industries across manufacturing, warehousing, logistics, and infrastructure trust Choice Prefab LLP for scalable PEB solutions. Our focus on faster project delivery, reduced steel consumption, and long-term durability makes us a preferred partner for engineers and developers alike.

When performance, compliance, and reliability matter, Choice Prefab LLP delivers structures engineered for the future.

Conclusion

Choosing between Zed Purlin and C-Purlin depends on performance, safety, and long-term efficiency. While C-Purlin suits small and low-load structures, Zed Purlin remains the preferred choice for industrial roofs due to its superior load capacity, wind resistance, and material optimisation.

Planning a PEB project?

Contact Choice Prefab LLP today to build smarter, stronger, and future-ready steel structures.