When you plan a new warehouse or industrial shed and start evaluating various Roof Sheet Manufacturers, the focus usually falls on the steel grade or design stability. These are certainly critical factors. However, there is an invisible shield that often gets ignored until rust starts eating away at your investment. That shield is the paint system, specifically its thickness.

For industrial clients in sectors like chemicals, pharmaceuticals, and petrochemicals, the longevity of the structure depends heavily on the Dry Film Thickness (DFT) of the coating. As one of the leading Roof Sheet Manufacturers in India, we at Choice Prefab believe that understanding DFT is just as important as choosing the right steel.

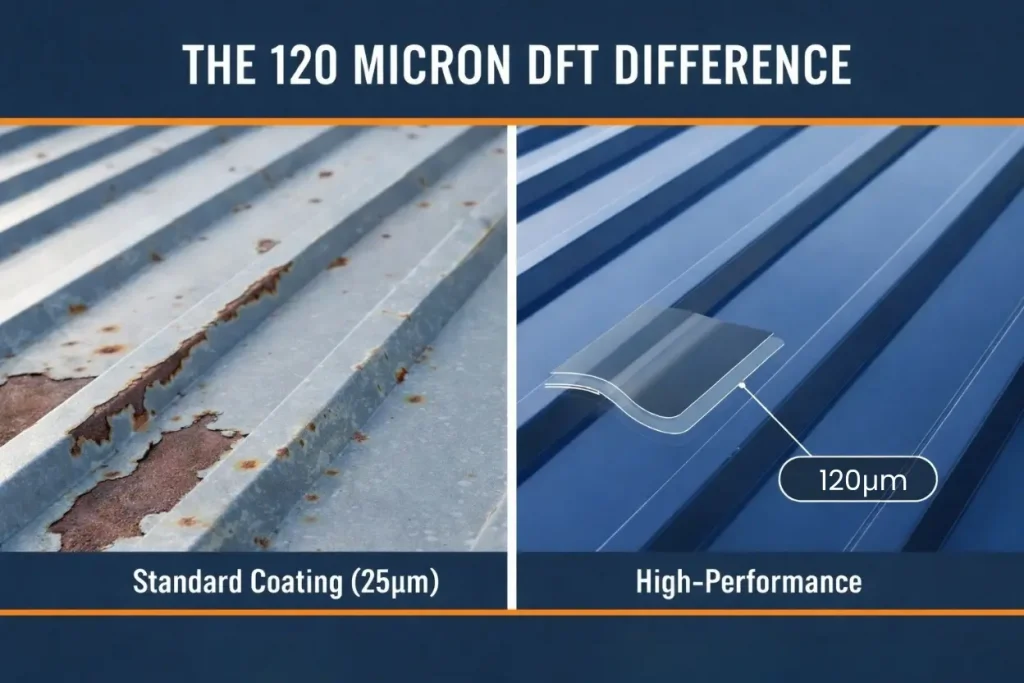

Here is why asking for a minimum of 120 Micron DFT can save you significant maintenance costs in the long run.

What is DFT and Why Does it Matter?

DFT stands for Dry Film Thickness. It is the measurement of the paint thickness after it has dried and cured on the metal surface. In the Pre-Engineered Building (PEB) industry, many Roof Sheet Manufacturers offer a standard coating of 30 to 60 microns. While this might look sufficient to the naked eye when the building is new, it often fails to withstand harsh industrial environments.

A thinner layer of paint creates specific risks:

- Micro-pores: Thin paint has tiny holes that are invisible to the eye.

- Penetration: Moisture and industrial fumes easily pass through these pores to reach the steel.

- Oxidation: Once moisture touches the steel, rust spreads underneath the paint, causing it to bubble and peel off.

At Choice Prefab, we adhere to a minimum DFT of 120 microns. This thicker layer acts as a robust barrier that seals the steel completely against moisture, salt in the air, and chemical exposure.

The Challenge for Chemical and Pharma Plants

Factories dealing with chemicals, plastics, and pharmaceuticals face a unique challenge. The air inside and around these facilities often carries aggressive elements such as:

- Acidic fumes

- Solvent vapors

- High humidity levels

If you use standard Metal Roofing Sheets with low DFT in such an environment, the corrosion process accelerates rapidly. We have seen standard structures start rusting within two years in chemical zones like Dahej or Ankleshwar.

To combat this, we use specialized Epoxy or PU (Polyurethane) paints based on the client’s specific requirement. When applied to a thickness of 120 microns or more, these paints provide superior resistance to chemical attacks.

Quality Starts with the Raw Material

A good paint job is only as good as the surface it protects. Many Roof Sheet Manufacturers might compromise by sourcing steel from secondary markets to cut costs. We take a different approach to ensure the paint bonds perfectly.

We strictly use high-grade steel with the following specifications:

- Standard: ASTM A572M, Grade 50, Type 1

- Grade: E350

- Source: Primary producers only (Tata, Essar, and JSW)

Applying a 120 Micron DFT coating on such clean, virgin steel creates a superior bond. This ensures the protective layer remains intact even during thermal expansion and contraction, preventing peeling.

Comprehensive Protection: From Purlins to Panels

Corrosion does not just attack the roof. It attacks the structural members, too. A complete anti-corrosion strategy must include the entire building envelope:

- Roofing Purlins: These secondary members support the roof. We apply the same rigorous painting standards to our Z and C purlins to ensure they remain rust-free.

- PEB Wall Panels: Our wall panels are treated to resist fading and chalking (formation of white powder), keeping your facility looking professional.

- Insulated Roofing Sheets: For temperature-controlled industries, we ensure the external facing sheet undergoes the same high-quality coating process.

The Economic Logic: Initial Cost vs. Lifecycle Cost

Specifying high DFT and Epoxy paints indeed adds a small percentage to the initial project cost. However, a strategic approach prioritizes the Total Cost of Ownership (TCO).

Choosing cheaper, thinner coatings often leads to hidden future costs:

- Production Downtime: Shutting down operations for repairs.

- Repainting Costs: Paying for labor and materials within 3-5 years.

- Structural Risk: deeply rusted frames may need complete replacement.

We construct Prefab Roofing Panels and structures designed to last. We even offer a one-year warranty on the whole building to back our promise of quality. Our successful execution of projects with tight deadlines, like the Astral Resinova plant in Dahej, proves that quality execution does not have to mean slow delivery.

Conclusion

Your industrial shed is a capital asset. It protects your machinery, your stock, and your people. Don’t let a few microns of paint be the weak link in your strong infrastructure.

When you evaluate Roof Sheet Manufacturers, ask them about their steel source and their paint DFT. If they hesitate, you know where to look. Our commitment to engineering excellence is holistic, spanning from precise Tekla-based structural designs to our robust 120 Micron paint application.

If you are looking for a partner who understands the science of durability, get in touch with us.

Explore our range of Roofing and Wall Panels here

Frequently Asked Questions (FAQs)

1. Why is 120 Micron DFT better than the standard 60 Micron DFT?

A higher Dry Film Thickness (DFT) provides a thicker barrier between the steel and the environment. 120 microns offers double the protection of standard coatings, significantly delaying the onset of rust, especially in humid or industrial areas.

2. What type of paint do you recommend for chemical plants?

For chemical, plastic, or pharma plants, we recommend Epoxy or PU (Polyurethane) paints. These offer high resistance to acidic fumes and chemical spills. As experienced Roof Sheet Manufacturers, we customise the paint type based on your specific industry hazards.

3. Do you provide a warranty on your roofing structures?

Yes, we provide a one-year warranty for the whole building. This covers the structure and ensures peace of mind regarding the quality of materials and workmanship we deliver.

4. Can you install these sheets on wide-span buildings?

Absolutely. We have successfully built structures with a clear span (width without a centre column) of up to 33.84 meters. Our high-quality paint ensures these large structures remain maintenance-free for a long time.