Steel structure design is the backbone of modern construction, especially when buildings must withstand wind and seismic forces. At Choice Prefab, a top-tier PEB manufacturer in Ahmedabad, innovative bracing techniques ensure safe, resilient structures across Gujarat and beyond.

Introduction

Safety and structural integrity are non-negotiable when designing steel structure design for buildings exposed to wind and earthquake forces. Well-engineered bracing systems play a pivotal role in resisting lateral and uplift loads, protecting both the structure and occupants.As a leading PEB manufacturer in Ahmedabad, Choice Prefab incorporates advanced bracing solutions into every custom structural steel building project to ensure reliability under extreme conditions.

Why Wind & Seismic Loads Shape Steel Structure Design

Understanding Wind Loads

Moreover, wind generates lateral pressure, uplift, and torsional forces on steel buildings. Since lighter structures are typical in steel construction, they can be more prone to uplift and drift if not adequately braced.

Seismic Forces

During an earthquake, forces like base shear, ground shaking, and sudden movements put stress on steel buildings. That’s why bracing is so important — it helps absorb this energy and protect the structure from damage.

The Role of Bracing in Structural Steel Buildings

To begin with, bracing systems stiffen frames, distribute lateral loads, and provide redundancy. In structural design, these systems are essential components that enhance resistance against both wind and earthquake forces. Furthermore, a PEB manufacturer like Choice Prefab integrates bracing into their standard practices to ensure compliance with IS codes.

Bracing Types for Wind & Earthquake Resistance

Here are the main bracing solutions used in modern steel buildings:

- Cross (X) Bracing: Provides excellent stiffness and energy dissipation, ideal for bays with limited frame rigidity.

- K‑Bracing: Transfers loads efficiently, though it may interfere with usable interior space.

- V (Chevron) Bracing: Common in warehouses, it offers strong performance during seismic events.

- Buckling‑Restrained Braces (BRB): BRBs maintain ductility during both tension and compression cycles and are increasingly popular in high-risk areas.

- Moment‑Resisting Frames: Walls and moment frames address aesthetics and open‑plan designs, where bracing limits flexibility.

- Rigid Diaphragms: Horizontal bracing (roof/floor) to transfer lateral forces to the brace systems.

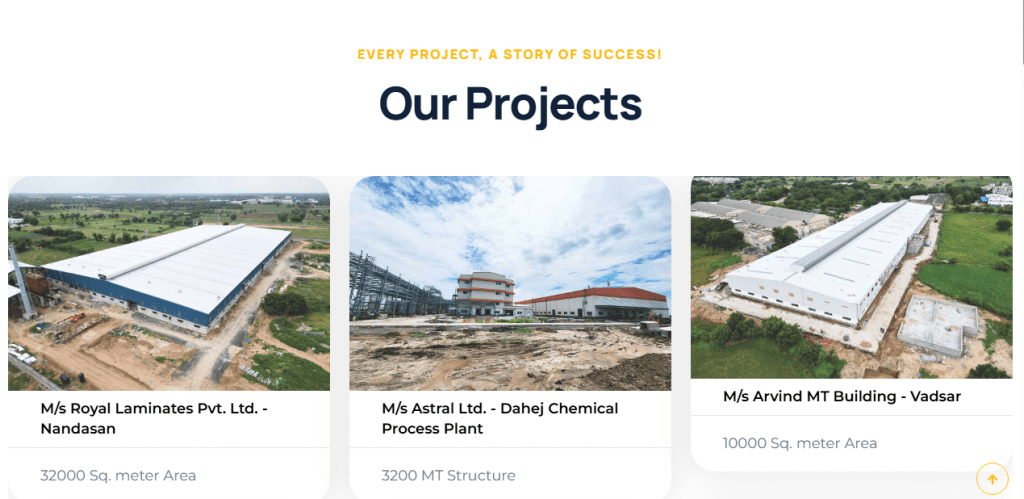

Choice Prefab Project Showcase: Bracing in Action

From Choice Prefab’s Our Projects page, here are real-world examples:

Warehouse in Ahmedabad – Heavy-Load Braced Frame

Choice Prefab installed horizontal and vertical cross-bracing to tackle intense wind uplift and lateral load.

This structural steel building features X‑bracing that significantly enhanced lateral stiffness without compromising open floor plan functionality.

Factory Extension, Gujarat – Chevron Bracing

To respond to seismic zone concerns, the PEB manufacturer in Ahmedabad used streamlined V‑bracing, optimising seismic load resistance while preserving internal utility space.

These examples demonstrate how Choice Prefab embeds steel structure design principles into every build, combining bracing solutions with high-quality fabrication and compliance as a certified PEB manufacturer.

Why Bracing Matters: Stabilising Forces, Saving Costs

Enhanced Stiffness & Strength: Bracing reduces drift under lateral loads.

Energy Dissipation: In seismic zones, steel dissipates earthquake energy as heat/work.

Lighter Foundations: Efficient bracing means smaller forces, smaller foundations, and cost savings.

Code Compliance: Designs meet IS1893 (seismic) and IS875 (wind), ensuring safety and legal approval.

Case Studies: Bracing Solutions in Real Steel Structure Design

Case Study 1: M/s Movish Motors Pvt. Ltd. – Sanathal

This large warehouse was built in an open area, where strong winds could easily hit the building from the sides. To handle this, the team added cross-bracing (X-bracing) in the side walls and roof. This made the structure stronger without using extra material.

As a result, the building became lighter, more stable, and could handle strong storm winds. It also followed all the rules under IS 875 standards. This project shows how smart design choices in steel buildings can lower risks and make the building last longer.

Case Study 2: M/s Astral Ltd. – Dahej Chemical Process Plant

For this seismic Zone III area, the building incorporated V-bracing (Chevron bracing) to balance functionality and safety.

By strategically placing braces only in non-operational bays, the team preserved internal flexibility while ensuring performance during earthquakes. The use of pre-engineered, modular components by this PEB manufacturer in Ahmedabad reduced construction time and improved precision.

Case Study 3: Agro-Processing Plant in Mehsana

Due to its expansive layout and rooftop equipment, this structural steel building required additional horizontal bracing. To address this, a rigid diaphragm system was implemented across the mezzanine and roofing panels, effectively redistributing seismic loads to the vertical braces.

This hybrid approach, therefore, demonstrates how customizable steel buildings can be when supported by thorough engineering and local expertise.

Innovations by PEB Manufacturers: Choice Prefab’s Approach

At Choice Prefab, a forward-thinking PEB manufacturer does more than just assemble steel frames — we engineer every detail of the steel structure for maximum resilience and performance. Here’s how we make the difference:

- Advanced Analysis Tools: Use of STAAD Pro, ETABS, and Tekla for load simulations.

- Modular Bracing: Pre-designed brace modules tested for multiple load conditions.

- Custom Geometry: Bracing adapted to meet aesthetic demands without compromising safety.

- Local Expertise: A PEB manufacturer in Ahmedabad understands Gujarat’s terrain, wind pressures, and seismic patterns better than pan-India providers.

By integrating digital design and precision manufacturing, Choice Prefab delivers bracing systems tailored to both project scale and location, whether it’s a coastal wind zone or a high-seismic inland region.

How to Choose the Right Bracing System

When planning your next steel building, consider the following:

| Factor | Impact on Bracing Design |

| Building height & dimensions | Taller structures need more lateral stiffness |

| Seismic zone | Demands energy-dissipating braces (e.g., Chevron) |

| Function & space use | Interiors may limit diagonal bracing options |

| Aesthetic requirements | May call for moment frames over visible bracing |

| Local codes | IS 875 (Wind), IS 1893 (Seismic), IS 800 compliance |

| Cost constraints | Balance between economy and structural performance |

Consulting with a professional PEB manufacturer ensures you choose the safest and most cost-effective bracing layout.

Conclusion For Steel Structure Design

In conclusion, smart steel structure design isn’t just about building fast; it’s about building safe. Wind and earthquakes are unpredictable, but with the right bracing system in place, your building can remain unshaken.

Choice Prefab, a trusted PEB manufacturer in Ahmedabad, combines technology, experience, and deep structural expertise to engineer bracing systems that protect life and investment alike. Whether you’re building a warehouse, industrial shed, or commercial facility, the right bracing makes all the difference.

Build strong. Build smart. Built with steel.